|

THE WAY GEARS WORK

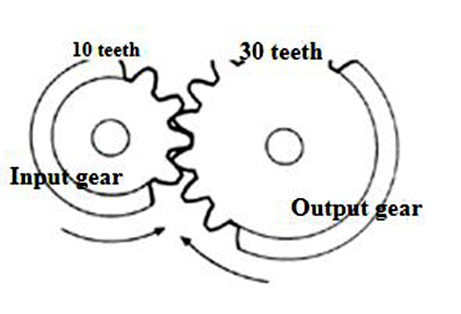

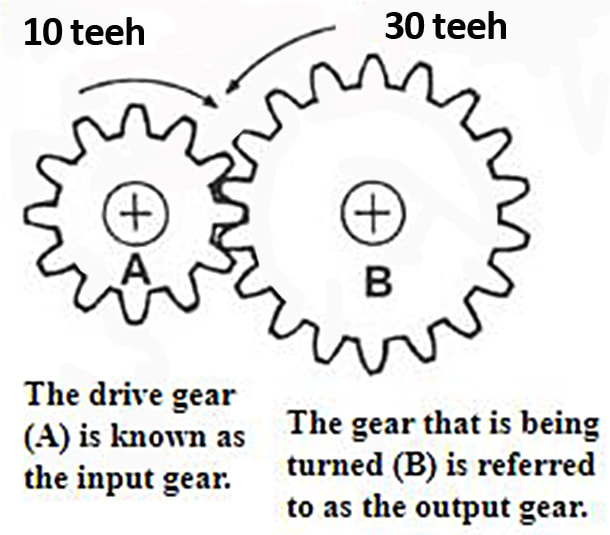

Gears are very versatile and can help produce a range of movements that can be used to control the speed of action. In basic terms, gears are comparable to continuously applied levers, as one tooth is engaging, another is disengaging. The amount of teeth each gear wheel has affects the action on the gear wheel it engages or meshes with. The gear wheel being turned is called the input gear and the the one it drives is called the output gear. Gears with unequal numbers of teeth alter the speed between the input and out put. This is referred to as the Gear Ratio. |

CALCULATING RATIOS

The following example shows how the ratios are calculated. If the input gear (A) has 10 teeth and the output gear (B) 30 teeth, then the ratio is termed 3 to 1 and is written down as 3:1

|

Gears also alter the direction of rotation. In the above example gear wheel A is rotating clock wise but as it turns, gear wheel B is moved anti-clockwise.

|

|

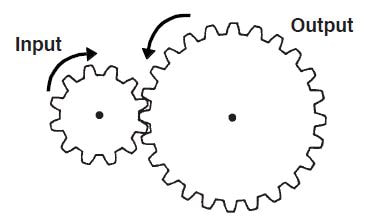

Stepping down has the advantage of producing more power although at a slower rate. This is often a big advantage with Automata as some of the mechanism can get stiff or are under tension and it makes turning the handle easier.

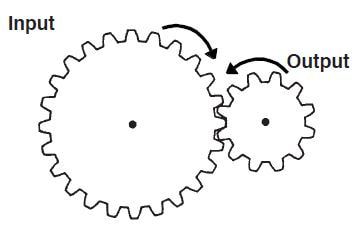

Stepping up produces a much faster output speed, but mechanically delivers less power. Be aware of this as you may find that your Automata doesn’t work properly or the handle is very hard to turn. However it is useful if you want something to move more quickly in relation to other things or just to go very fast |

Stepping Down Gears

Stepping Up Gears

|